Making Legos involves intricate processes and materials. How much does it cost to make Legos? The answer lies in a detailed breakdown of production expenses. From raw materials to manufacturing, each step contributes to the final cost. Understanding these elements sheds light on the fascinating world behind the creation of these beloved building blocks. Let’s explore the intricacies of costing Legos and unravel the mysteries of their production expenses.

How Much Does It Cost to Make Legos?

Welcome, all Lego lovers! Have you ever wondered how much it actually costs to make those colorful and fun bricks that we all adore? In this article, we are going to delve deep into the world of Lego production and uncover the secrets behind the pricing of these beloved toys. So, grab your favorite Lego set and let’s explore together!

The Fascinating World of Lego Production

Before we can understand the cost of making Legos, we need to take a peek behind the scenes into the fascinating world of Lego production. Legos are not just ordinary toys – they are precision-engineered plastic bricks that go through a meticulous manufacturing process to ensure their quality and durability.

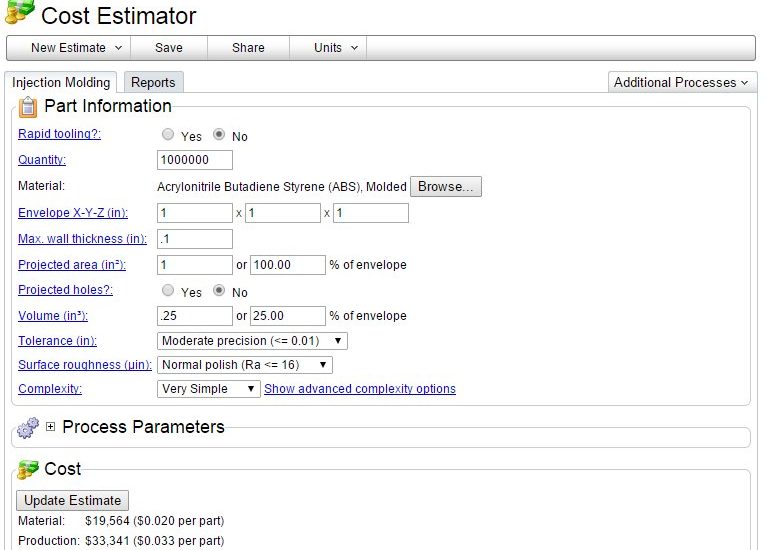

Each Lego brick is made from a special type of plastic called ABS (acrylonitrile butadiene styrene), which is known for its strength and impact resistance. The manufacturing process involves injecting molten ABS plastic into molds that are precisely designed to create the intricate shapes and details found in Lego bricks.

The Cost Breakdown of Making Legos

Now, let’s break down the various costs involved in making Legos:

1. Raw Materials

The primary cost of making Legos lies in the raw materials used, especially the ABS plastic. The quality of the plastic directly impacts the durability and interlocking ability of the bricks. Lego invests in high-quality ABS plastic to ensure that their bricks are long-lasting and compatible with each other.

2. Manufacturing Process

The manufacturing process of Legos is highly automated and efficient. Modern machinery is used to mold, cool, and inspect the bricks to meet Lego’s strict quality standards. The cost of maintaining and operating these sophisticated machines adds to the overall production cost.

3. Design and Development

Another significant cost factor in making Legos is the design and development of new sets and pieces. Lego employs talented designers and engineers who work tirelessly to create innovative and engaging sets that capture the imagination of Lego fans around the world. The cost of research, design, and testing is integrated into the final price of each Lego set.

4. Packaging and Distribution

Once the Legos are manufactured, they need to be packaged and distributed to stores worldwide. The cost of packaging materials, transportation, and logistics all contribute to the final retail price of Lego sets.

Factors Affecting the Cost of Legos

Several factors can influence the cost of making Legos:

1. Economy of Scale

Lego benefits from economies of scale due to its large production volume. By producing a high quantity of bricks, Lego can spread out its fixed costs over more units, reducing the cost per brick.

2. Innovation and Technology

Investing in innovative technology can help Lego streamline its production process and reduce costs. New advancements in materials and machinery can lead to cost savings in the long run.

3. Licensing and Partnerships

Lego often collaborates with popular franchises and licenses their characters and themes for Lego sets. These partnerships can come with additional costs in the form of royalties and licensing fees, which can impact the overall cost of production.

Understanding the Price of Legos

When you purchase a Lego set, you are not just buying a bunch of plastic bricks. You are investing in a world of creativity, imagination, and endless possibilities. The price you pay reflects the quality, design, and craftsmanship that go into making each Lego set.

Next time you build a Lego masterpiece, remember the intricate process and dedication that goes into creating those colorful bricks. The cost of making Legos may not be just about money, but the value they bring to our lives through play and creativity.

In conclusion, the cost of making Legos is a complex interplay of raw materials, manufacturing processes, design, and distribution. While the exact cost breakdown may vary, one thing is certain – the joy and inspiration that Legos bring to millions of fans worldwide are truly priceless.

So, the next time you snap together a Lego creation, think about the journey that tiny plastic brick has taken to reach your hands. And remember, the cost of making Legos is more than just dollars and cents – it’s about the endless possibilities and boundless imagination that Lego sparks in all of us.

How Much Would it Cost to Buy Every LEGO Set? #lego #legoaddict #legosets

Frequently Asked Questions

How is the cost of making Legos determined?

The cost of making Legos is determined by various factors such as the quality of the raw materials used, production processes, labor costs, packaging, distribution, marketing, and any additional features or licenses associated with the product. All these elements contribute to the overall cost of making Legos.

What are some of the main expenses involved in producing Legos?

Some of the main expenses involved in producing Legos include the cost of acquiring high-quality plastic materials, the expenses related to manufacturing and assembling the bricks, packaging costs, transportation fees to distribute the products, as well as marketing and advertising expenses to promote the brand.

Why do certain Lego sets cost more than others?

Certain Lego sets cost more than others due to factors such as the complexity of the design, the number of pieces included in the set, any licensed themes or characters associated with the product, exclusive features, limited editions, and the inclusion of technology components like motors or lights. All these factors can influence the final price of a Lego set.

How do economies of scale impact the cost of making Legos?

Economies of scale play a significant role in reducing the cost of making Legos. As the production volume increases, the cost per unit decreases due to efficiencies in manufacturing, bulk purchasing of materials, and optimized distribution processes. This can lead to lower overall production costs, which may be reflected in the retail price of the Lego sets.

Final Thoughts

In conclusion, the cost to make Legos varies based on factors like materials, labor, and design complexity. How much does it cost to make Legos? The overall expense includes production, packaging, marketing, and distribution. With global sourcing and efficient manufacturing processes, Lego strives to keep costs reasonable while maintaining quality. Understanding the intricacies of Lego production sheds light on the pricing structure and the value offered to consumers.